“DRATCH” PLANT CONVERSIONS

Batch – Drum Plant Conversion

Batch plants do a fine job of making “specialty” mixes in small quantities. However, they waste a lot of time screening your materials, dividing it into specific sizes then blending it back together and mixing it all in a pugmill. This wasted time cost you production.

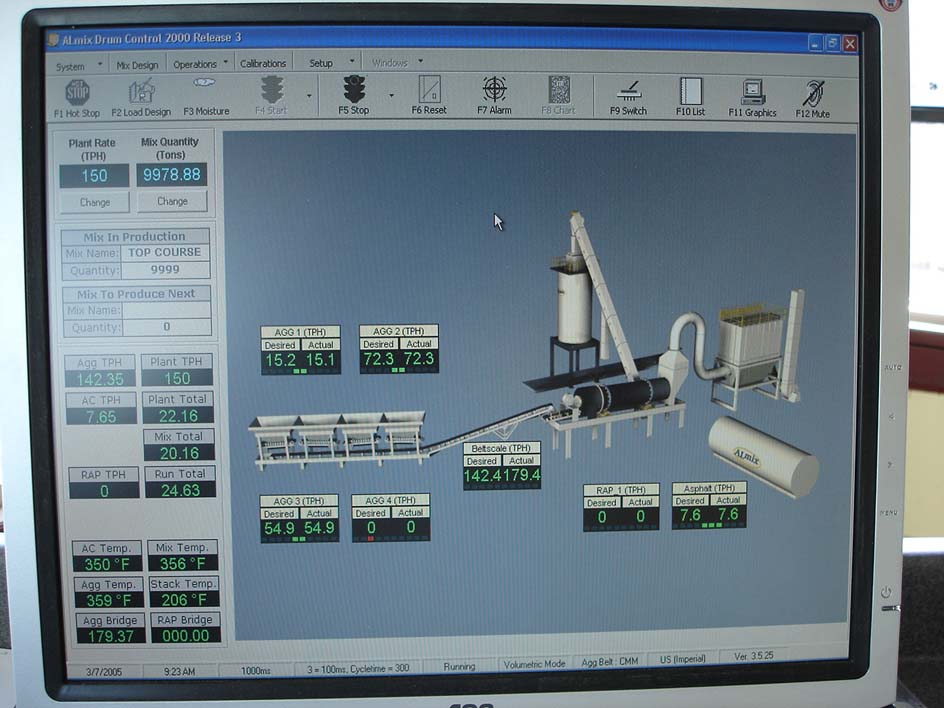

Drum plants make mixes “continuously”, so they do not waste time in unnecessary activities like screening and pugging the mixes. The downside to a drum plant is that it is difficult to make small quantities without significant wasted materials. It is also difficult to switch a drum plant between small quantities of different mixes.

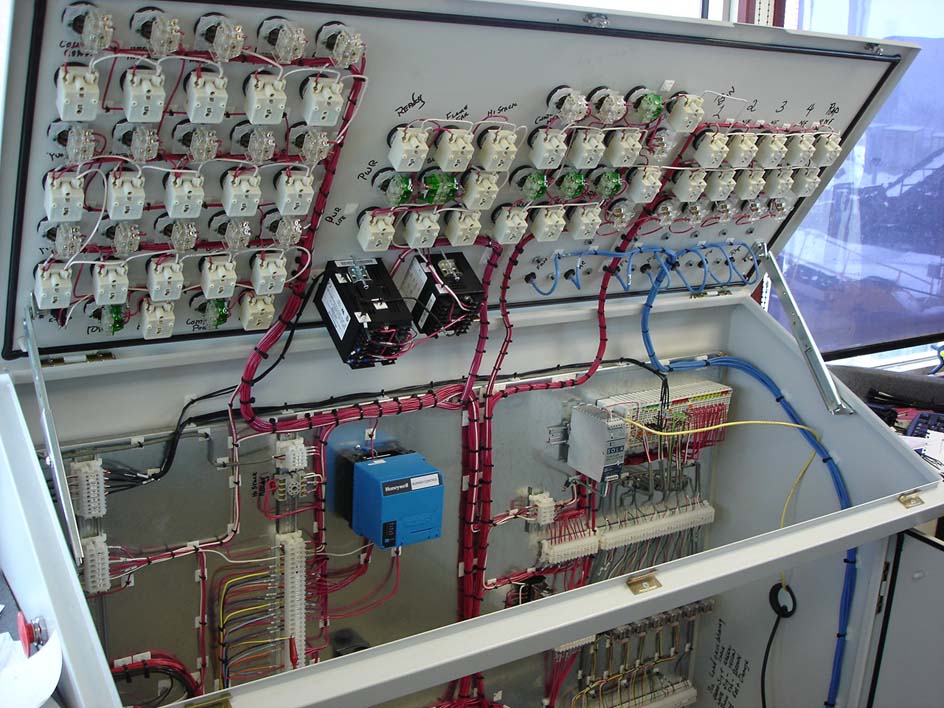

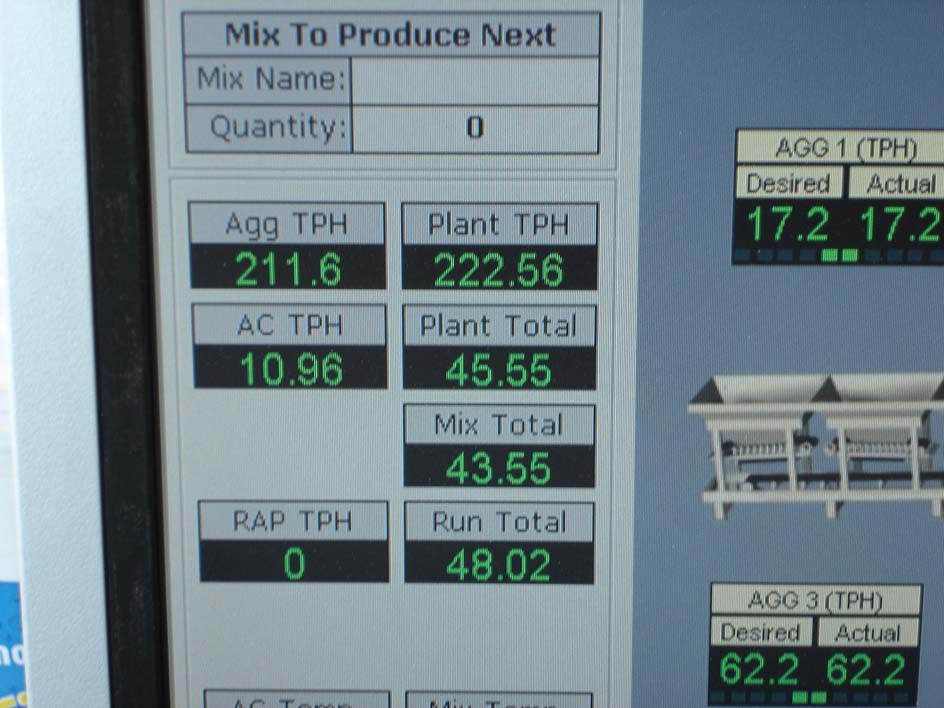

A “Dratch” plant is a combination Drum/Batch plant. We set your plant up so that it can run as either a batch or a drum plant. Under certain conditions it can run simultaneously as both. The following pictures are of an east coast plant we converted earlier in the year. When we arrived, this batch plant was running at 60 tons per hour with no RAP. When we finished, I personally ran the plant at 220 tons per hour with virgin and 170 tons per hour with 25% RAP.

Many more pictures available. Call to request more information.

Call Cliff Mansfield- 541-352-7942

Email Cliff- cmconsulting@hotmail.com

*********